Green, Smart, Commercial and Residential Construction Worldwide

Forged by Strategic Partnership

Using a patented revolutionary green construction system combined with cutting-edge embedded sustainable technologies, we build smart structures with a steel, hazard tough frame covered inside and out with abuse-resistant, weather-proof, long-lasting 100% green coatings.

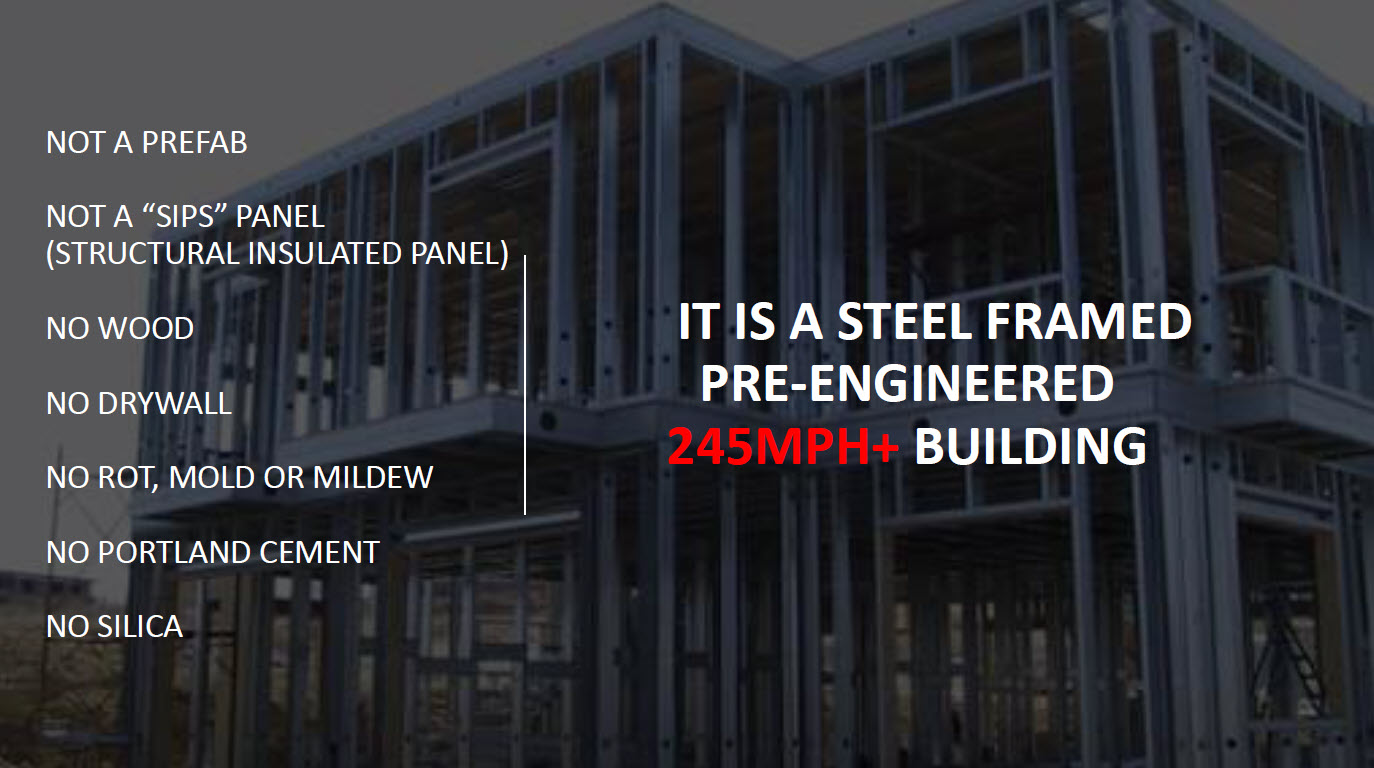

The Major Difference

Materials

No toxic materials in our structures. Only environmentally friendly materials used.

- NO WOOD (wood burns, splits, warps and is food for insects)

- NO PORTLAND CEMENT (largest CO2 producer globally since 1875)

- NO GYPSUM BOARD (weak, low impact, grows mold when wet)

- NO SILICA SAND (now regulated, crystalline silica is carcinogenic)

True Green Construction

No trees to cut down, creates thousands of unskilled labor jobs onsite, and high energy efficiency.

- WILL NOT GROW MOLD OR MILDEW

- CAN BE HOSED DOWN AFTER A FLOOD WITH NOTHING TO REPLACE

- SUPER INSULATED OVER 50% PROVEN ENERGY SAVINGS

- SUPER INSULATED STEEL FRAMED STRUCTURE TO MEET IBC CODES

- 100% RECYCLABLE

All Hazards Resistant

Designed to withstand all hazards with zero damage for continuity of living/operations.

- 245 MPH CATEGORY 5 HURRICANE RESISTANT (Miami Dade Tested and certified)

- SEISMIC ZONE 4 EARTHQUAKE RESISTANT

- FIRE RESISTANT COATINGS ENCAPSULATE THE INSULATED PANELS

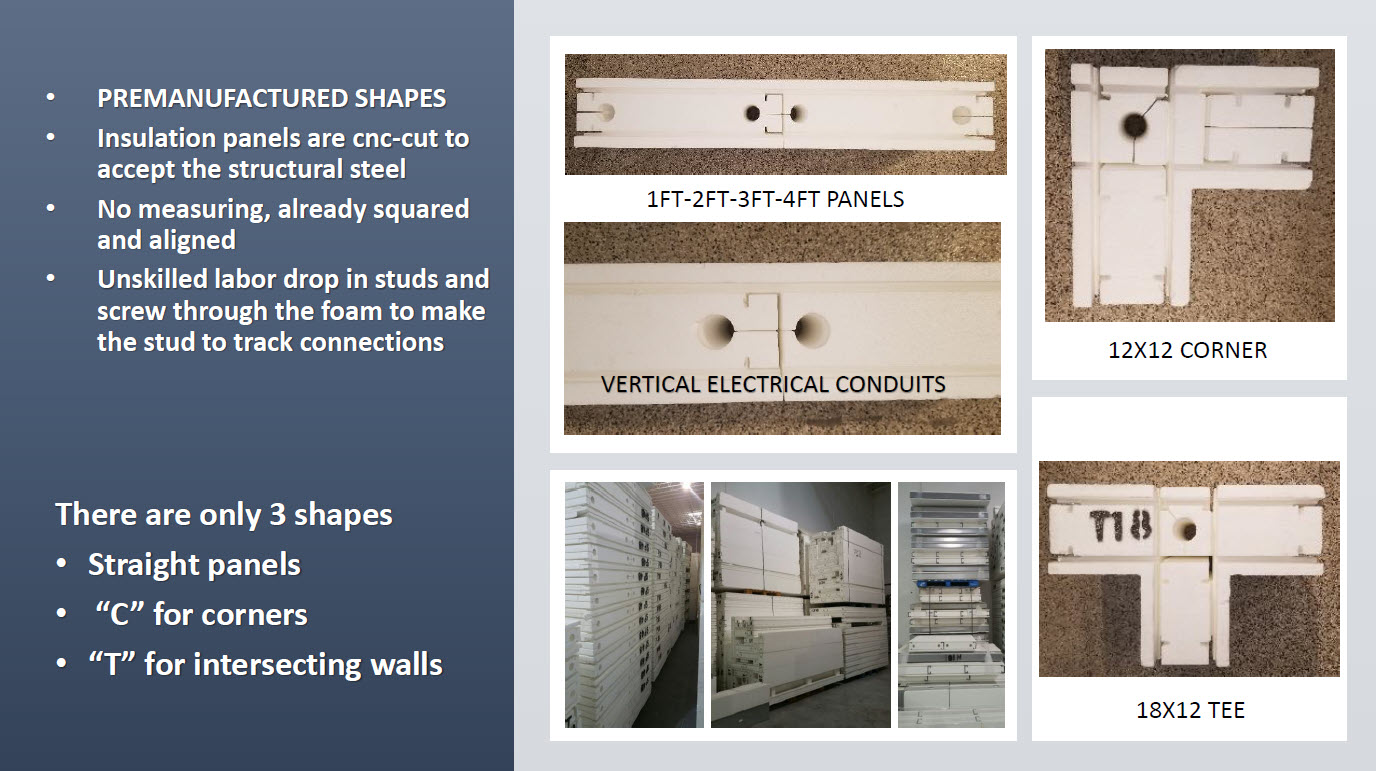

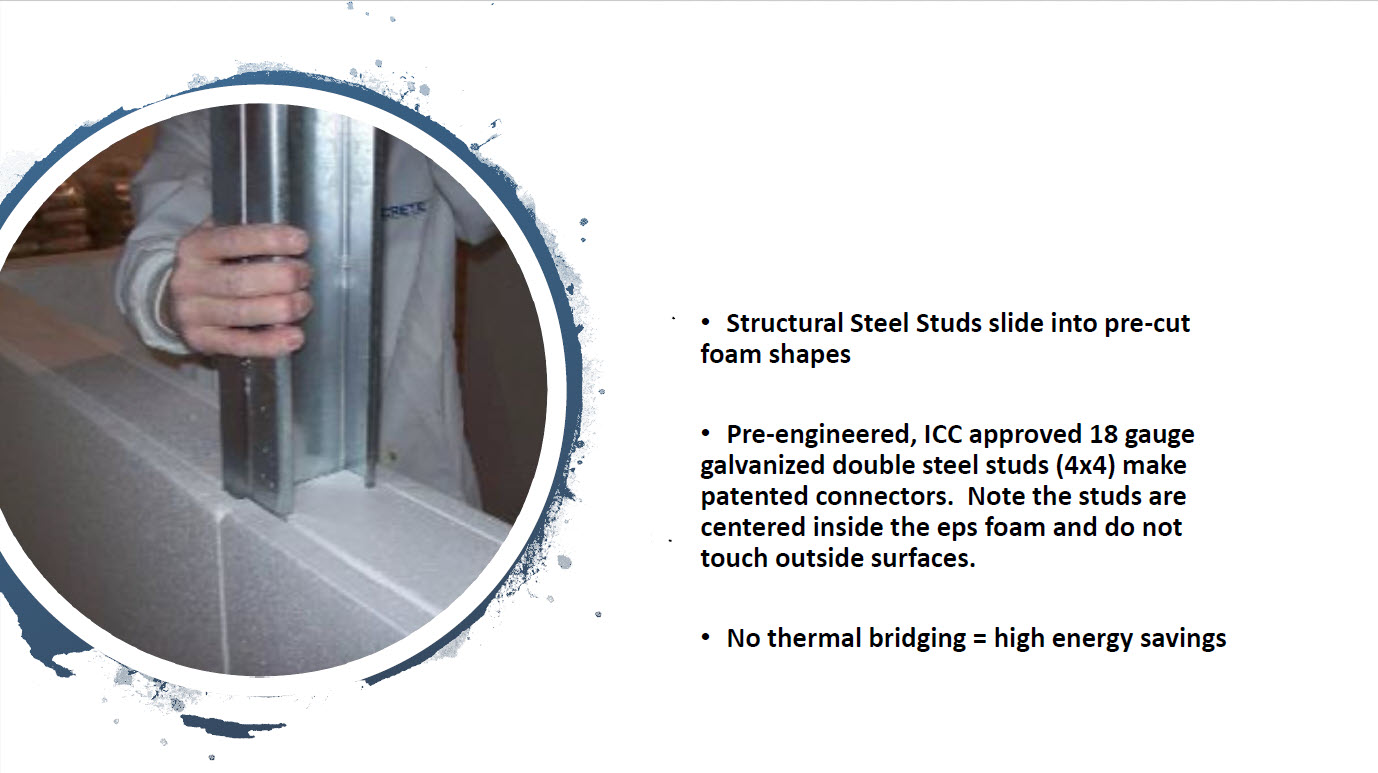

How We Build It

Smart from the Ground Up

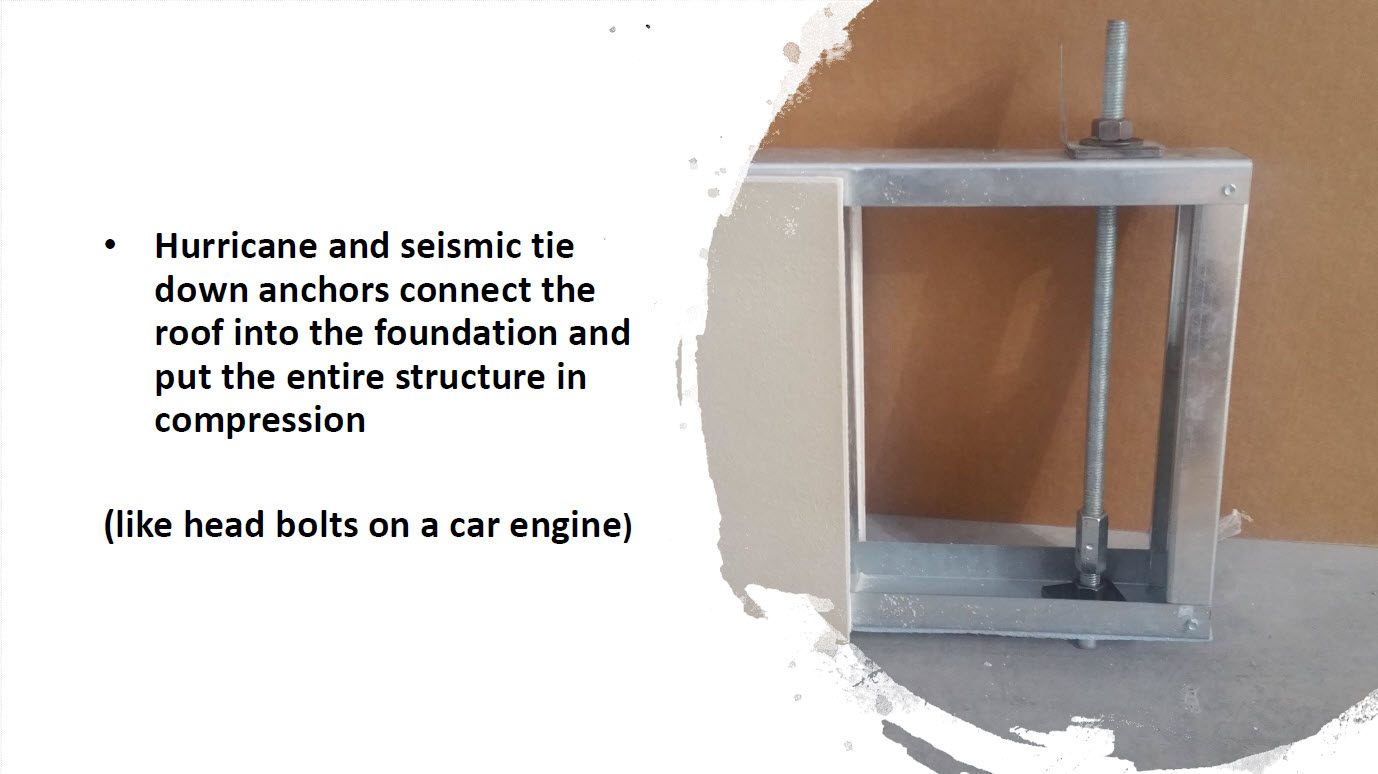

The steel frame is installed directly on the slab. Structural studs slide into precut ICC code approved, thick EPS insulation panels (recycled, laser-cut Styrofoam – any shape). Pre-engineered galvanized double steel studs make our patented connectors. Hurricane and seismic hold-down anchors connect the roof into the foundation eliminating uplift in hurricanes by pulling the roof and house into the slab. The walls serve as a post-tension system, firmly attached to the concrete slab.

Mechanical, Electrical, and Plumming (MEP)

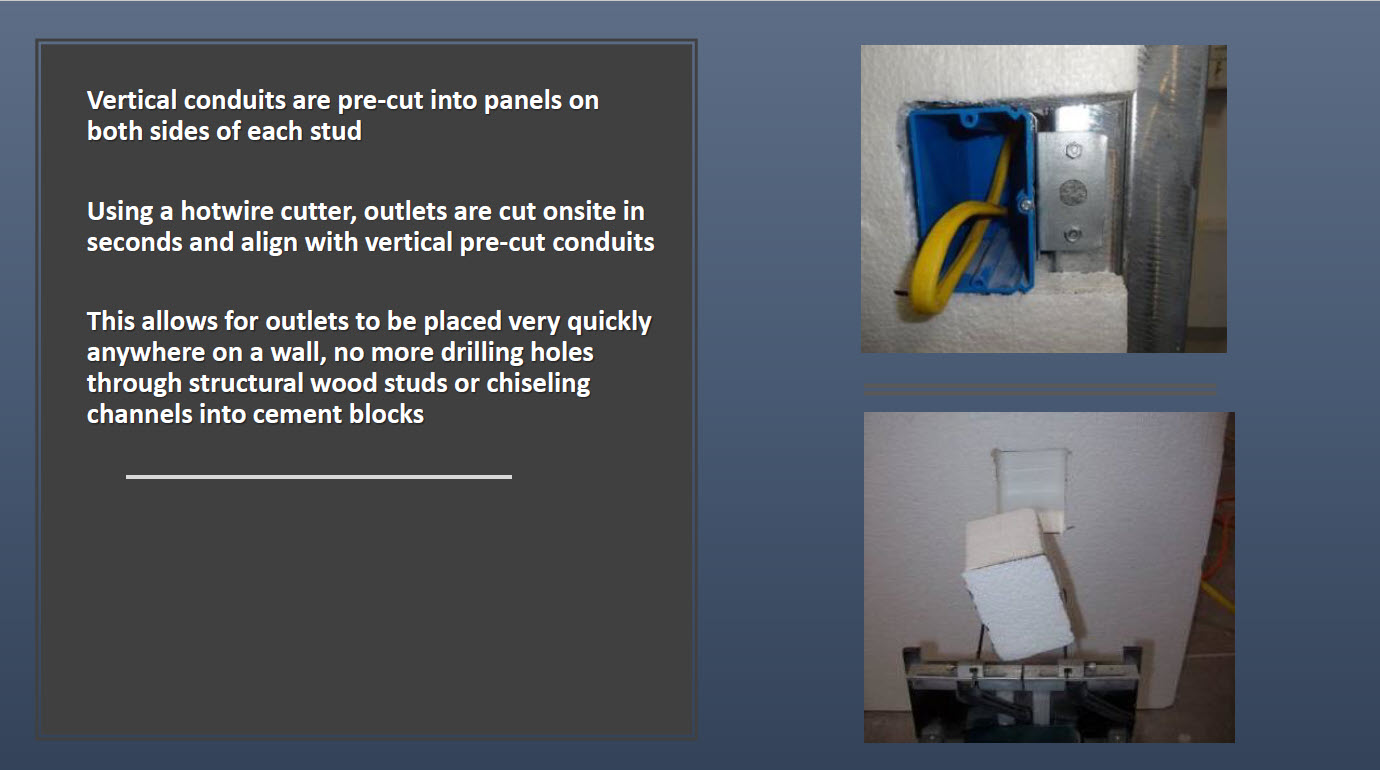

Vertical conduits are pre-cut into panels on both sides of each stud location ready to pull down wiring from above without having to drill through each stud.

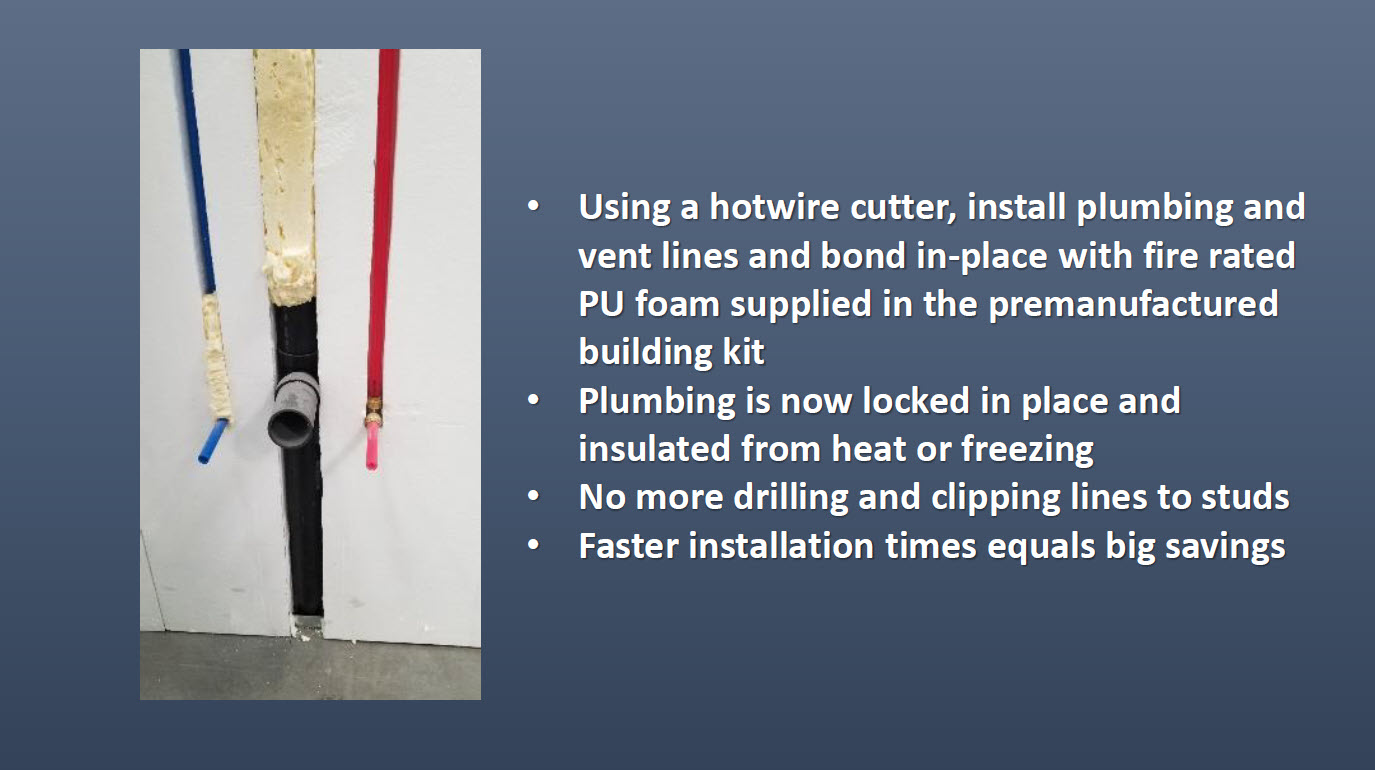

Install plumbing lines into walls in minutes. Locked in place with urethane foam, hot water stays hot while cold water stays cold. No freeze thaw issues or burst pipes due to freezing weather. No more drilling through wood studs. This means less labor cost for high-priced plumbers. Simply place the precut two-piece plumbing insert up against the wall next to where it is needed, scribe a line both sides of the insert and cut out the foam in the wall panels and insert this one. Call for inspection with just the rear piece in place, then cover with the over half after approvals.

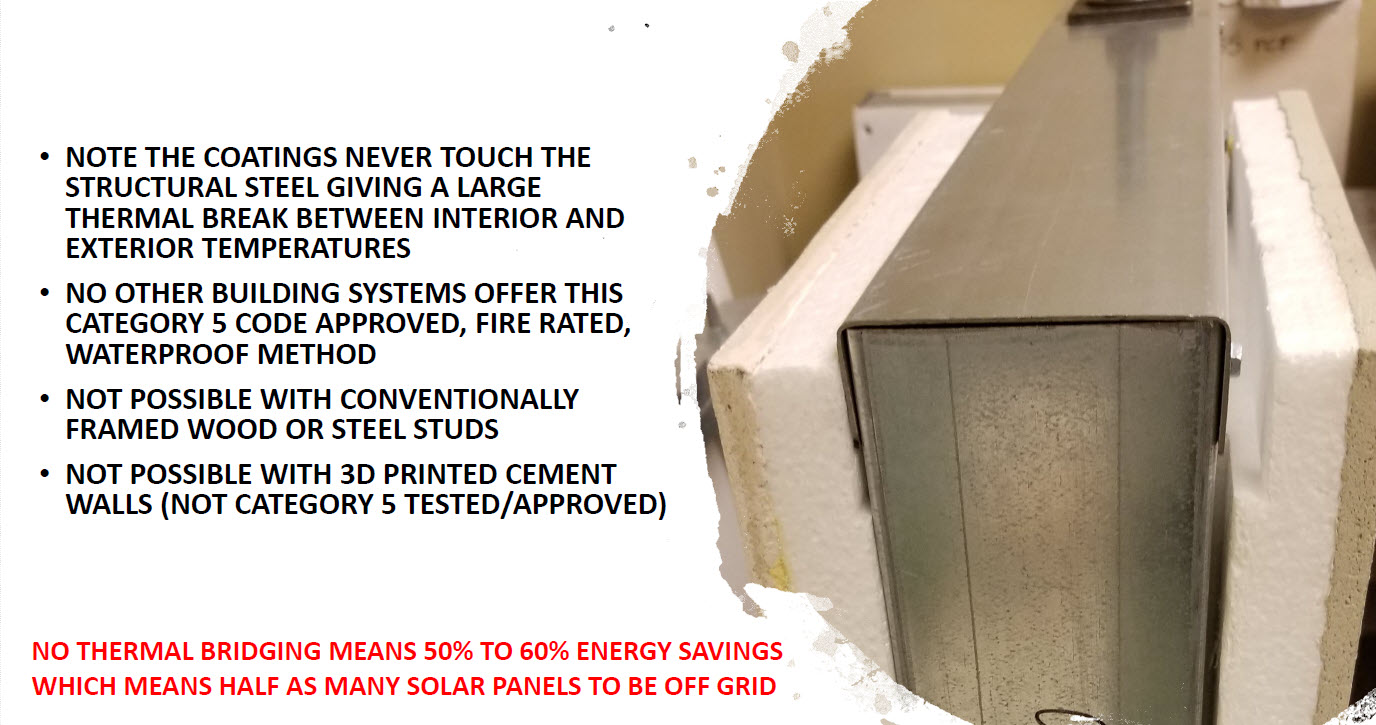

The Coatings

High-performance coatings are applied directly over the EPS foam panels. PlasterMax on the inside and StuccoMax on the outside. All panel seam lines are covered over to create a seamless and durable ceramic finish. No drywall, no mold or mildew, and it is extremely high abrasion and impact resistant.

Seeing is Believing

High Energy Efficiency

Construction that is truly green and efficient with tested results.

Homes we construct come in at a 2 on the H.E.R.S. Index while the average new traditionally built home with R19 insulation comes in between 70 and 100. Usage for heating and cooling is extremely low and if solar panels are used to power the home, you don’t need as many. This means a lower long-term total cost of operations and ownership for residential and commercial construction.

Fire and Salt-Water Resistant

Our Green Steel construction system exceeds the 15-minute fire test and is proven to be salt-water resistant.

Interior Fire Test – Intertek Testing Labs

Our construction system passed NFPA 286, a 15-minute Corner Burn Test at 1,400 degrees Fahrenheit.

At only 1/8″ (3mm) thickness, there was zero smoke, no combustion, and the official 15-minute test continued on for 22 minutes without failure.

Flood and Salt Water Resistant

Our structures can survive flooding. There’s no drywall, fiberglass insulation, or wood studs that may rot. Walls remain intact even when submerged in salt water for 21 days. ASTM 60” water column test, under pressure of 5ft of water since March 28th, 2012, and still ongoing. Column is epoxied to the StuccoMax over 1” low density EPS foam and filled with 60” of water pressure. Substrate foam is removed beneath water column to see if water droplets or penetration occurs. Test as seen in photo below is now over 11 years old with NO water penetration!

Weather Resistant – Proven

Accelerated weathering testing between StuccoMax and STO, Dryvit, Parex, Omega and other synthetic stuccos that have all been tested equally, clearly show the degradation (on the right) of synthetic stuccos versus StuccoMax on the left:

StuccoMax remains firmly bonded to the EPS foam even after 100 cycles followed by 40 freeze thaw cycles. Nothing we are aware of exists in the stucco industry that compares.

Category 5 hurricane and F4 tornado resistant

245 MPH SUSTAINED WIND SPEED WITHOUT FAILURE.

- ASTM E330-14 TAS 202-94 WINDLOADS 245MPH SUSTAINED (CATEGORY 5+) F4 TORNADO

- ASTM E72-05 COMPRESSION

- ASTM E72-05 TENSION

- ASTM E72-05 RACKING

- ASTM E331-00 AIR INFILTRATION

- ASTM E331-00 WATER INFILTRATION

- ASTM E1996-14 TAS 201-94 LARGE MISSILE IMPACT TEST (12 IMPACTS)

- ASTM 1886-13 TAS 203-94 CYCLIC LOADS (RACK AND SHEAR, SEISMIC)

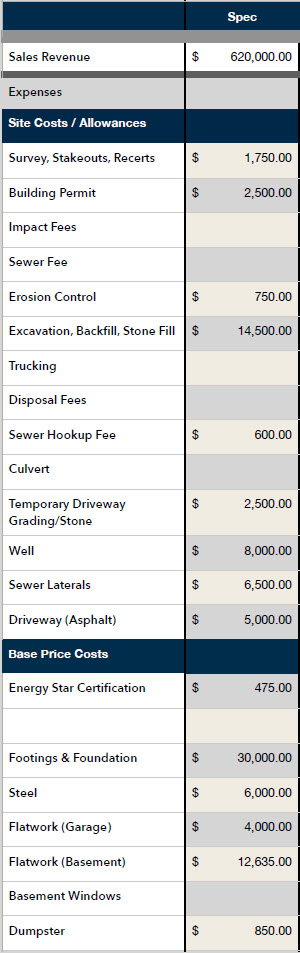

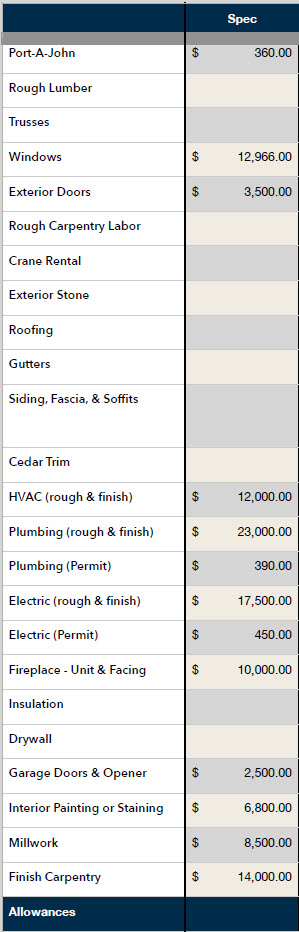

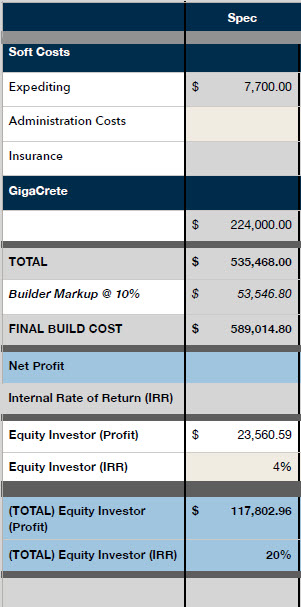

The Economics: Laying It All Out

With our green construction building system, Internal Rate of Return (IRR) for projects is realized at more than 20% and in a quarter of the time for traditional construction.

The Future of Green Construction

In the past, being “Green” typically cost 15% to 20% more. This is no longer the case because the entire way we do construction has changed-not just the materials. Speed to build utilizing premanufactured components means lowers costs, less labor, less waste, and less clean-up. What took months, can now take weeks. The savings are realized in less labor and time, which means finished construction costs are less than conventional building costs with greater immediate and long-term benefits in energy savings and durability.